PVD - Physical Vapor Deposition

PVD stands for "Physical Vapour Deposition." The PVD coating serves to make watches more durable, increase their resistance, and enhance their appearance.

During the vacuum coating process, very fine layers of hard materials in vapor form are applied to the base material, forming a comprehensive coating layer. The entire powder coating must take place in a vacuum chamber to prevent a reaction between vapor and air. Layer thicknesses can start in the nanometer range. However, by repeatedly performing the process, layers up to several micrometers can also be built up.

The great advantage of the vacuum coating process is that the atomized material does not undergo any chemical reactions with the surface. Adhesion occurs solely through the process.

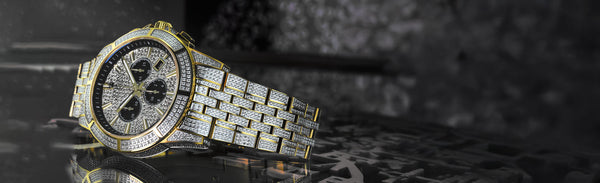

The conventional PVD process results in a strong black surface. Black watches are therefore usually treated with the PVD process and can be easily recognized. In addition to the conventional coating with black material, there is also PVD gilding. Here, a very thin layer of metal is vaporized and applied to the watch. This results in not a black surface, but a golden or rose gold coating.

In PVD gilding, identical processes are used as in conventional PVD coating. However, instead of spraying lead or graphite, gold particles are applied.